R&D Projects for the Valorization of Wood Cellulose

R&D Projects for the Valorization of Wood Cellulose

Nanocellulose

Research initiatives focus on the use of nanocellulose as a strength enhancing additive for renewable and

biodegradable matrix polymers such as PLA. Research also concentrates on the development of porous nanocellulosic materials for insulation &

packaging.

New coatings are also being developed with outstanding barrier properties in food packaging and printing

paper applications.

New developments concentrate on the use of nanocellulose as a rheological modifier in cosmetics

(thickener), pharma (tablet binder) and paint applications.

Levoglucosenone (LGO)

Levoglucosenone (LGO) is a biology derived chemical which can be produced from waste cellulose. Current

developments focus on LGO conversion to new polar aprotic bio-solvents. These new solvents are

alternatives to NMP, DMF and DMAc which are under significant regulatory pressure worldwide due to

their toxicity.

UV filter Selection for Cosmetics

UV filter Selection for Cosmetics

The following steps will help you select the right UV filter(s) for your cosmetic formulation:

- Set out clear objectives for the performance, aesthetic properties and intended claims for the formulation.

- Check which filters are permitted for the intended market.

- If you have a specific formulation chassis that you wish to use, consider which filters will fit with that chassis. However if possible it is best to choose the filters first and design the formulation around them. This is especially true with inorganic or particulate organic filters.

- Use advice from suppliers and/or prediction tools such as the BASF Sunscreen Simulator to identify combinations that should achieve the intended SPF and UVA targets.

These combinations can then be tried in formulations. In-vitro SPF and UVA testing methods are useful at this stage to indicate which combinations give the best results in terms of performance. The test results, along with the results of other tests and assessments (eg. stability, preservative efficacy, skin feel), enable the formulator to select the best option(s) and also guide the further development of the formulation(s).

Related Read: Alternative In-Vitro SPF Sunscreen Test Method »

UVA/SPF: Upgrade your Test Strategy for Regulatory Compliance

Talk to Julian Hewitt where he will help you avoid running expensive tests and show you how to support formulation work &

UVA/SPF claims for your targeted markets (EU, US, Japan). He will also help you learn about conducting right test at the right time (in-vitro or in-vivo) & how to interpret test results better.

Available UV Filters for Cosmetics & Personal Care Products

View a wide range of UV filters / sunscreen agents available today, analyze technical data of each product, get technical assistance or request samples.

What's Next?

Learn strategies to formulate natural sun care cosmetics. Talk to Julian Hewitt where he discusses the key parameters of ‘natural’ products and help you optimize in

practice your formulations to get appealing natural sun care products with real life cases.

R&D Projects for the Valorization of Lignin from Wood

R&D Projects for the Valorization of Lignin from Wood

Carbon Fiber

Lignin represents a potential low-cost source of carbon suitable for displacing synthetic polymers, such as:

Polyacrylonitrile (PAN) in the production of carbon fiber.

Using lignin in the carbon fiber manufacturing

process improves:

- Raw material availability

- Decreases raw material sensitivity to petroleum cost, and

- Decreases environmental impacts

The goal of replacing steel panels with lightweight, yet strong, carbon

fiber-reinforced plastics is to significantly reduce vehicle weight and improve fuel economy.

Resins and Adhesives

Resins and adhesives offer a large opportunity, especially for formaldehyde-free applications.

Formaldehyde is currently considered a carcinogen and its banishment from consumer and packaging

goods and building products is highly likely in the near term.

Technical needs and challenges for lignin in

this area center on:

- Effective, practical means for molecular weight and viscosity control

- Functional group enhancement to improve oxidative and thermal stability, for example:

- Carbonylation

-

Carboxylation

- Amination

- Epoxidation, and

- De-etherification

- Consistent mechanical processing properties

- Control lignin color, and

- Precise control of cure kinetics

Product consistency in these application targets will also

be a technical challenge.

Polymer Modifiers

Polymer modifiers can be simple, low-cost fillers or may be high-value additives that improve various

polymer physical or performance properties. Currently, lignin use concentrates on the former; Current

research is concentrating on the latter by creating technologies that improve polymer:

- Alloying

- Mutual solubility

- Cross-linking, and

- Control of color

Relevant technologies include:

- Predictable molecular weight control

- Facile introduction of reactive functionality, and

- Polyelectrolytic functionality

Monomeric Molecules

Very selective depolymerization, also invoking C-C and C-O bond rupture, could yield a plethora of complex

aromatics that are difficult to make via conventional petrochemical routes. These complex aromatics include:

- Propylphenol

- Eugenol

- Syringols

- Aryl ethers

- Alkylated methyl aryl ethers

Research is concentrating on developing technology that would allow highly selective bond-scission to capture the monomeric lignin building block structures. However, markets and applications for monomeric lignin building blocks would need to be developed.

This development is therefore longest-term and currently has unknown market pull for large-scale use. Since, most of the chemical industry is used to single, pure-molecule raw materials, using mixtures of products in

a chemical raw material feed, as would arise from lignin processing, constitutes a challenge.

BTX Molecules (Benzene, Toluene, Xylene)

Developments concentrate on non-selective depolymerization technologies in the form of C-C and C-O

bond rupture. This can lead to the production of aromatics in the form of BTX plus phenol and includes

aliphatics in the form of C1 to C3 fractions.

Development of the required non-selective chemistries is part of the long-term opportunity. But, it is likely to

be achievable sooner than highly selective depolymerizations. In fact, some of the past hydro-liquefaction

work with lignin suggests that, with further development, this concept is a good possibility.

R&D Projects for the Valorization of Sugars from Wood

R&D Projects for the Valorization of Sugars from Wood

Single Cell Protein (SCP)

SCP consists of microorganisms such as filamentous fungi, yeast, algae, and bacteria that are rich in

protein. R&D projects are ongoing to use sugar streams generated by wood biorefineries for the

production of single cell protein.

SCP can be used as a protein source in fish feed. SCP can be more a nutritional alternative to the current

products used in the aquaculture such as soybean meal in particular. SCP has a high B vitamin content and

a tunable amino-acid profile. This GMO-free product is safe, nontoxic and contains no fatty acids.

Bio-surfactants

Industrial research focuses on the development of new bio-based surfactants, thickeners, emulsifiers,

texturing agents from C5 and C6 pure sugars derived from wood hemicelluloses.

These research initiatives

are market pull projects to meet the requirements of the cosmetics industry in a continuous search for new

bio-based products and effects.

Bio-based Polymers

There are R&D initiatives which focus on the conversion of C6 sugars (glucose, mannose) derived from

wood hemicelluloses to diacid and diamines monomers. They are then used for the development of bio-based polyamides.

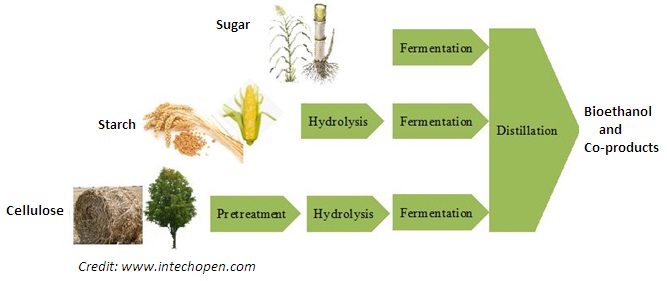

Bio-fuels

R&D initiatives are focused on the development of new biomass fractionation technologies, like:

- Acid-based

- Enzyme-based

- Solvent-based, or combinations of these chemistries

- Supercritical water hydrolysis

- Steam explosion…

All these technologies can economically fractionate the wood biomass to sugar and lignin streams which all

need to be valorized.

Research concentrates on developing the most efficient process (biomass treatment,

enzymes production, fermentation and distillation) to produce a cost competitive 2G ethanol equivalent to 1G

bioethanol.

Bioethanol Production from Biomass

Bioethanol Production from Biomass

R&D Projects for the Valorization of Extractives from Wood

Feedstock Related Barriers

UV filter Selection for Cosmetics

Market Related Barriers