TAGS: Sun Care

This article was first published in 2017 and is revised in 2022.

Sunscreens play a vital role in fighting aging caused due to the sun. The consumption of sunscreens has seen a rise since consumers have started understanding the significance of these products.

Sunscreens play a vital role in fighting aging caused due to the sun. The consumption of sunscreens has seen a rise since consumers have started understanding the significance of these products.

Formulating a sunscreen product may not be as easy as you might think. There are a lot of aspects taken into consideration. Amongst them, the most important thing to remember is that the stability of the formulation and UV results are not always predictable.

1 + 1 ≠ 2 when it comes to sunscreen formulation stability or performance!

In fact, when formulating these types of products, you must use good formulation principles and theory; but the actual product, stability and SPF rating you achieve could be different from what you have anticipated.

Additionally, with many consumers expecting a minimum SPF of 50+ cosmetic formulators face significant aesthetic, stability and performance challenges with increasing SPF. But interestingly, all these three aspects can be overcome by improving the skin feel and spread of the product in the following ways:

- The way the product spreads and adheres to the skin is crucial to achieve a good SPF rating. Where the product allows for a thin but homogeneously dispersed layer of UV filters to be applied over the skin, the best combination of consumer aesthetics and SPF rating will be achieved.

- The product base must hold UV filters homogeneous throughout the shelf life of the product. So, stability and even dispersion are crucial.

- UV filters often feel quite tacky or may come in solid or powder form as a raw material. This ensures that they are solubilized effectively in a suitable base for a good skin feel and spreadability, however, preventing crystallization over time, since it is a crucial aspect of consumer aesthetics and product stability.

Before we get into the details, let's take a look at the principles behind a sunscreen formulation.

General Principles of Sunscreen Formulation

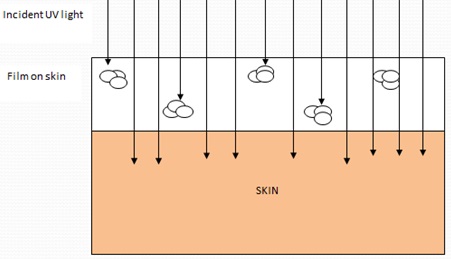

To help you understand this principle, consider the following diagrams. Both these diagrams provide the same quantity of incidental UV light and representative UV filters. In the figure below the UV filters agglomerate, hence they will not provide much UV protection.

Poor formulation can lead to agglomeration of UV filters and low SPF protection

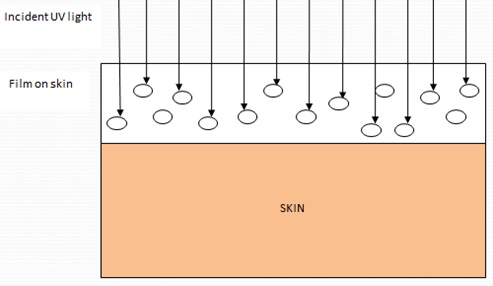

Poor formulation can lead to agglomeration of UV filters and low SPF protectionIn the figure below the UV filters are homogeneously dispersed, hence they will achieve a much better UV protective benefit.

Homogenous distribution of UV filters will enable the best SPF results to be achieved

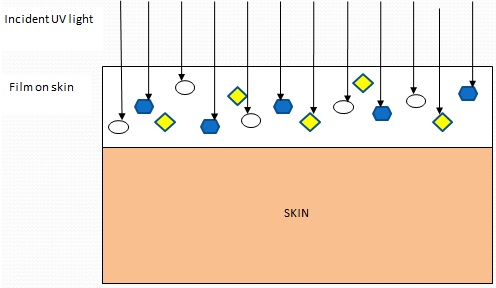

Homogenous distribution of UV filters will enable the best SPF results to be achievedRefer to the diagram below, where a combination of UV filters is used. A potentially synergistic UV protective benefit may be obtainable, which means less UV filters are required to achieve the same or better UV protective benefits – this results in less raw material use and less cost, and can enable better consumer aesthetics and stability to be achieved from the finished formulation.

A combination of UV filters is used to achieve UV protection

A combination of UV filters is used to achieve UV protection

Note: In all diagrams, a uniform film from the base product is required over the skin as a fundamental formulation requirement – it is crucial to get a smooth, even film on the skin to have any hope of good UV distribution and product coverage. Note: In all diagrams, a uniform film from the base product is required over the skin as a fundamental formulation requirement – it is crucial to get a smooth, even film on the skin to have any hope of good UV distribution and product coverage.

|

Factors to Consider while Choosing UV Filters to Achieve the Right Formulation Type

When formulating sunscreen products, you will need to formulate them to suit the solubility of the UV filters you will be using AND/OR

select the UV filters to suit the type of product that must be created (e.g. o/w or w/o lotion or cream; stick (balm) or spray). When considering the type of formulation you need to create and/or the UV filters you want to use, take note of the following points:

- Company philosophy may dictate what UV filters, emulsifiers, polymers and other ingredients you can or can’t use; as well as the regulatory requirements of the country in which it will be sold.

- The form of the product will also dictate the type of ingredients you need to select, in some cases, you may not be able to achieve the requested form of product using the materials you are allowed to use by company philosophy and/or regulatory requirements.

- If the UV filters are oil-soluble you will need to ensure they are dispersed in a suitable quantity of compatible lipid material and this will add to the % content of the oil phase of your formula.

- Most UV filters are soluble/compatible with the oil phase of a formula.

- Where a high content of oil-soluble UV filters are used, you will have a high content of oil phase ingredients in your formula (which includes the lipid to disperse the UV filter + the UV filter itself + ‘spreadability’ factors); due to the high oil phase content of many of these types of formulations, w/o emulsions may need to be created.

- Some UV filters are soluble or compatible with polar lipids (e.g. esters); while others are soluble or compatible with non-polar lipids (e.g. mineral oils). You will need to check for the polar or non-polar lipid compatibility of the UV filters you are using to ensure they are put into a suitable base formulation – if you don’t select the right polarity of lipids, the UV filter can crystallize out over time.

- If the UV filters are water-soluble, you will need to ensure they are dispersed in a suitable quantity of water and this will add to the % content of the water phase of your formula.

- Chelating agents and/or photo-stabilizing agents may be required to help achieve long-term stability and prevent early degradation or crystallization occurring in your formula – look for this information on the raw material technical/product datasheet to ensure you incorporate necessary stabilizing factors into your formulation.

- W/o emulsions will favor better water-resistant properties, although high water-resistant properties can be achieved with o/w where the suitable film-forming polymers are used. A variety of waterproofing polymers can be added to improve the barrier properties of a product both in and out of the water.

- The choice of emollients you select will be crucial to help ensure even spreading of the product over the skin, disperse UV filters, provide positive aesthetic properties to the formula and potentially enhance the SPF rating achieved. You should use a combination of fast and medium spreading oils with slow spreading UV filters for best skin feel and spread. If you change any emollient in your formulation after SPF testing has been conducted, you will need to get SPF testing conducted again as the way the product spreads (which is affected by the types, amounts and combination of emollients used) will impact on the SPF result obtained.

With a number of UV filter chemistries available in the market, are you struggling to find the best ingredient for your sun care formulation?

Determine the Amount of UV Filter to be Used

When determining the amount of each UV filter to use in your formula, use the following tips; but remember, the base of the product including emulsifiers, emollients and polymers used, will have a significant impact on the actual UV rating achieved. To determine a starting amount of UV filter to use:

- Look for UV absorbance rating and wavelength information to help you determine the relative UV protective ability of a UV filter. For example, ethylhexyl methoxycinnamate (octyl methoxycinnamate/octinoxate) has a UV absorbance E max λ @ 1%/1cm of 308nm @ 830. This means its maximum UV absorbance is at 308nm (UVB protection) with a relative ratio of 830 at 1%/1cm. It is, therefore, able to absorb a little more than 4 times the same wavelength of light, for example, as homosalate, which has a UV absorbance E max λ @ 1%/1cm of 308nm @ 170-180.

The key here is to look at the ‘ratio’ of absorbance, which for ethylhexylmethoxycinnamate was 830, compared to 170-180 for homosalate. This means 4 times as much homosalate would be needed, all things considered, to offer the same protection as ethylhexylmethoxycinnamate – but there may be regulatory, skin feel, compatibility, synergy or other formulation considerations that would mean you need to use one or the other or both.

- As well as the wavelength of light, you need to consider how the UV filter absorbs/reflects to determine what combinations can achieve a suitable ratio of UVA:UVB protection.

- Refer to product data sheets and information from suppliers to provide you with the best guidance on combinations of ingredients. Ask for research data and sample formulations with stated SPF to determine appropriate amounts to add to your formulation. SPF testing is relatively costly and adds to product expense so you need to do your best to ensure a sufficient SPF will be reached without using excessive amounts of sunscreen agents. When combining sunscreen agents you may need to check for patents covering formulation techniques and blends.

You may at this point be wondering why not just use one UVA filter and one UVB filter to simplify a formulation. The answer is that just using one UV filter usually will not:

- Yield the required UVA:UVB ratio and in any case, not yield the required SPF (UVB) rating

- Achieve the required protection ratings to be achieved within permitted use limits/regulations

- Achieve the required protection ratings whilst enabling suitable skin feel, spreadability and/or consumer aesthetics

- Enable a cost-effective formulation to be made that can achieve the required SPF rating

Plus, there are generally significant synergies achieved when a good combination of UV filters is used in a formulation; enabling a good skin feel, high SPF and UVA:UVB ratio to be achieved at a suitable cost with good stability.

Basic Considerations Behind Sunscreens

In addition to ensuring a suitable SPF and safety profile can be achieved, when formulating sunscreens you will also need to consider issues of:

| Considerations |

Description |

| Cost |

- Sunscreen agents and water-resistant polymers can add significantly to the cost of a formulation so you will need to ‘cost out’ the formula in theory before starting any development work.

- Clients requesting sunscreens may need to be informed of additional costs such as SPF testing (with or without water resistance testing) and listing and/or registration expenses before proceeding with the formulation.

- Unrealistic budgets will need to be discussed with the concept developer before development commences. In many cases, concept developers may simply be unaware of all the formulation difficulties and legislative requirements associated with sunscreen products.

|

| Availability |

- Sunscreen agents may only be available in large pack sizes and can be costly. Before selecting a sunscreen agent you should find out the pack size, expected shelf life and costs to check its suitability for your formulation and manufacturing requirements.

- All sunscreen agents should be checked with the appropriate regulatory databases to ensure they can be used before you include them in a formulation.

- Check the lead time of a product, particularly as summer approaches. Will supply over the peak periods be able to meet demand? If there is uncertainty as to supply or long lead times, you may want to reconsider the use of that sunscreen agent.

|

| Company/Product Philosophy |

- If the company philosophy is based on using natural products then only sunscreens such as zinc oxide or titanium dioxide are suitable for selection. Note these are not natural or naturally derived, but are accepted by some Organic Certifiers and consumer groups as the ‘natural’ sunscreen choices. Be careful not to use products coated in silicon or its derivatives. Using a silicon-coated material is not providing consumers with the type of ‘natural’ product they may be seeking, and using a coated material will alter performance and spreadability.

- Safety evaluation tests should be conducted (either real time or repeat insult) to ensure the safety of the product for consumer use.

- Polymers will often provide water resistance, stability and improve the spreadability and aesthetics of a product, but may not be suitable in products claiming to be naturally derived.

|

| Formulation Compatibility |

- Sunscreen agents will affect the stability of a product and must be stable themselves within the product.

- The use of antioxidants not only improves protection against free radicals in the skin exposed to UV light, but will also improve the photo-stability of the formulation and protect against rancidity of natural oils if used in the finished product.

- Some UV agents are not compatible with carbomer or may need chelating agents added to the formulation to ensure stability. Refer to information data sheets to check for any specific requirements of ingredients before you use them.

- The method of manufacture may need to be adjusted to suit individual formulation requirements. Consider also potential issues when scaling up the formula from the lab to production batches.

- Scale-up should be conducted on all formulas at a maximum rate of 10-20X for each previous batch. For example, if produced in the lab at 200g, the next scale-up would be lab production of 4kg, then pilot production of up to 80kg and then full scale production of up to 1600kg. Sunscreen formulations are particularly prone to scale-up and stability issues, so suitable scale-up steps should be used to help minimize or contain scale-up issues at each stage.

|

| Finished Product Performance Characteristics |

- Some sunscreen agents have undesirable smells; the use of small amounts of fragrance may be necessary to hide such odors but should be checked they do not lead to undesirable fragrances over time.

- The spreadability and skin feel of these products are important not just for consumer acceptance, but may also affect product performance. This is a very important factor to consider during formulation and when making product samples.

|

How to Improve Spread & Skin Feel in High SPF Formulations?

In order for sunscreens to achieve an SPF of 50+, they typically need to contain around 25-30% w/w (or more) UV filters. Most UV filters do not have a pleasant skin feel on their own. They range from tacky, heavy feeling oils to chalky, sticky powders.

Remembering that the more evenly a product spreads, the better the SPF results will usually be… Let’s see how such a high proportion of a formulation can feel better on application:

Clever UV Filter Combination

Using just one UV filter in the formulation will not yield the required:

- UVA:UVB ratio

- Protection rating within permitted use limits

- Suitable skin feel

- Spreadability

- Consumer aesthetics, or

- Cost-effectiveness

A good combination of UV filters in a formulation can enable the best possible SPF rating and UVA: UVB ratio at a potentially lower input. The less UV filters needed, the easier it is to improve the skin feel of these products.

Coated Powders

There are multiple suppliers with coated

titanium dioxide or

zinc oxide options. Coatings vary too, including various silicone derivatives, esters and natural lipid derivatives to suit a variety of company philosophies. When coated, these powders take on enhanced slip and aesthetic properties. Also, they get ‘wetted’ much more easily for faster and more homogeneous incorporation in bulk manufacture. The coatings used must suit the polarity of the lipid medium you are also using in your formulation.

Dispersions

These are viscous liquid preparations where the titanium dioxide or zinc oxide is dispersed within a lipid medium. The lipid medium can vary significantly and be selected to suit company philosophy and required aesthetics. The powder is usually combined into the dispersion format through triple roller mill processing (or similar). This not only grinds the powders into very fine particle size but also ensures an even dispersion.

While the cost of a pre-prepared dispersion is greater than purchasing and mixing the individual ingredients alone. The resulting SPF rating and skin feel are dramatically improved by using dispersion. The lipid medium of the dispersion will often make up the bulk of the lipid phase of the formulation, so choose carefully.

Combination of Emollients

The choice of emollients selected will be crucial to help ensure:

- Even spreading of the product over the skin

- Dispersion of UV filters

- Positive aesthetic properties to the formula, and

- Potential enhancement in the SPF rating

The diagram below shows how this recommended combination provides an overall aesthetically pleasing spread of product over time.

A visual example of how light and medium feeling emollients enhance the skin feel of slow spreading UV filters

A visual example of how light and medium feeling emollients enhance the skin feel of slow spreading UV filtersStabilizing Agents are Essential – But Beware!

The use of

appropriate stabilizing agents are essential in SPF formulations to keep the high proportion of UV filters homogeneously distributed throughout the required shelf life. But, careful selection and evaluation of resultant skin feel is crucial!

- For a start, make sure your stabilizing material is suited to the continuous phase of the formulation, otherwise, it could contribute to agglomeration and a shorter than expected shelf life.

- Next, you need to make sure that the stabilizing network it forms throughout the continuous phase enhances homogeneous distribution of the UV filters selected to avoid any ‘balling’ effect on application.

- Finally, selection of the stabilizing agent should be made to improve the potential slip of the formulation, making clay stabilizers (for example, bentonites in o/w emulsions) or organoclays (for example, stearalkonium bentonite in w/o emulsions), particularly suitable materials.

Steps to Build your Sunscreen Formulation

When putting your formulations together, make sure you:

- Select your UV filters first – see the key points above to assist you with your UV filter selection.

- Once you’ve selected your UV filters, think about how you are going to disperse and have them spread well – this will then ‘pre-determine’ if your formula will be w/o or o/w based on the content of lipid-soluble materials you will be using OR alternatively, you may find your selection of UV filters is driven by the need to specifically create a w/o or o/w base product.

- Once you’ve determined the continuous phase, you then need to select materials to stabilize that product form to ensure stability, spreadability (which ultimately impacts performance) and comply with product philosophy.

- Build-in additional stabilizing factors e.g., gums/polymers, suitable emulsion stabilizers, antioxidants, preservatives, chelating agents, etc. as required.

- Build-in additional performance and/or marketing ingredients e.g., waterproofing or ‘actives’ to build a product story.

- Prepare your samples and rework your samples until desired aesthetics have been achieved.

Putting it All Together...

As with any formulation, the selection of materials can be significantly impacted by overall cost and company philosophy considerations. This never so true, or so difficult, as when formulating high SPF products. Get the best skin feel out of your SPF products by:

- Making a careful selection of the combination of UV filters and/or coated or pre-dispersed powder filters required to yield the best SPF and UVA:UVB ratio to material input

- Utilizing fast and medium spreading lipids

- Using appropriate stabilizing agents to suit the continuous phase and encourage slip

Safety of Sunscreens

Not only is the SPF rating of a sunscreen product important, but also its safety. Sunscreen products must be tested for possible reactions because chemical UV agents can cause irritation. The use of fragrances and preservatives in combination with UV agents may also cause irritant reactions in the skin. In general, the higher the % used of a chemical sunscreen, the greater its potential to cause irritation.

Combining two to three chemical agents will not only reduce the % input of each and therefore the irritation potential, but will often increase the SPF performance of the finished product. Synergistic blends are a good way to reduce irritation and improve performance.

View all non-irritant ingredients used in sun care products »

Formulating sunscreen products can be a challenging but enjoyable experience and knowing you are helping consumers protect their skin from damaging UV rays with an aesthetically pleasing and high-performing product is perhaps the best reward of all! Make sure you follow the key steps and guidance provided here and your formulations will have a sound theory for the best possible results.

Meet UVA/SPF Regulatory Requirements for your Targeted Markets

Get your sun care cosmetics to comply faster with today’s UVA/SPF regulatory requirements by upgrading your testing strategy to overcome challenges resulting from the lack of global harmonization of test protocols and labelling criteria.

Find Suitable Sunscreen Agents for Cosmetics

View a wide range of sunscreen agents available in the market today, analyze technical data of each product, get technical assistance or request samples.

Happy Formulating!